PRODUCT DEVELOPMENT

Think. Design. Build.

Magnetic levitation-based product

Magnetic Levitation System – Innovation in Electromagnetic Suspension

Third-year student A. Manideep created an electromagnetic levitation system using feedback control within an illuminated hexagonal frame as part of the Product Design and Development course. The product precisely levitates objects with real-time height tracking on a digital display.

Spec :

Frame Shape: Hexagonal, illuminated acrylic frame

Levitation Range: 5 mm – 40 mm above the electromagnet

Dimensions: 300 mm hex frame, 250 mm height

"This project gave me hands-on experience in blending physics, embedded systems, and design, boosting my skills in product development and innovation." — A. Manideep

Automatic UV Sanitizer

Developed by third-year Product Design student Shaik Vasif, this autonomous mobile robot uses UV-C light and sensors to disinfect hospitals and offices safely and efficiently. With IoT integration and an energy-efficient design, it reduces manual effort and minimizes human exposure to pathogens.

Spec :

Navigation : Autonomous with obstacle detection sensors

Power Input : Rechargeable battery pack (24 V DC,)

Special Features : Safety cut-off sensors

Dimensions : 450 mm × 350 mm base, 1200 mm height

"This project was a valuable hands-on experience in robotics, embedded systems, and IoT, helping me overcome sensor integration and automation challenges." — Shaik Vasif

Automatic UV Sanitizer

Portable Mini 3D Printer

Portable Mini 3D Printer

Developed by third-year Product Design student Satheesh, this compact FDM 3D printer offers high-precision, portable printing for students, hobbyists, and professionals. USB and SD card support and a 0.4 mm nozzle make it perfect for rapid prototyping and creative exploration.

Spec :

Frame Shape : Compact portable design with 300 mm × 300 mm × 350 mm

Printing Tech : Fused Deposition Modeling (FDM)

Build Volume : 150 mm × 150 mm × 150 mm

Nozzle Diameter : 0.4 mm

"Building this mini 3D printer was an exciting journey! It deepened my skills in mechanical design, electronics, and software integration while showing me the power of precision and portability." — Vignesh

Automatic Tennis Ball Thrower

Developed by third-year engineering student Poojitha C. H, this motorised tennis ball thrower enhances training by launching balls with adjustable speed, spin, and angles. It blends mechanical precision, sensor-based automation, and real-time control to simulate real-game scenarios.

Spec :

Frame Shape : Portable wheeled base with angled launcher

Speed Range : Adjustable, 20 – 120 km/h

Capacity : 50 – 100 tennis balls (hopper based)

Dimensions : 600 mm × 400 mm × 800 mm

"Building the Tennis Ball Thrower deepened my understanding of automation and control systems—solving motor and trajectory challenges made it an exciting and rewarding experience!" — Poojitha C. H

Automatic Tennis Ball Thrower

Target Shooting System

Smart Shooting System

Created by student Meghana, this interactive target shooting system uses sensor-based hit detection and real-time scoring to enhance precision, engagement, and user experience. Instant feedback keeps users motivated and supports skill development.

Spec :

Frame Shape : Modular target frame with sensor panels

Operation Mode : Automated target shooting with hit detection

Capacity : Supports multiple target zones

Dimensions : 500 mm × 500 mm × 100 mm

"Developing this project improved my understanding of automation and real-time data processing." — Meghana

SMART Suitcase

Designed by student S. Abineshwari, the Smart Suitcase autonomously follows the user, avoids obstacles, and offers mobile app control for seamless travel. It includes GPS tracking, a secure lock system, and a built-in charging battery for added convenience.

Spec :

Frame Shape : Compact suitcase with integrated drive wheels

Control System: Microcontroller with mobile app integration

Tracking System: GPS-enabled real-time location tracking

Security Feature: Digital secure lock system

Dimensions: 550 mm × 350 mm × 250 mm

"This project enhanced my skills in robotics and IoT integration, giving me hands-on experience in motor control, obstacle detection, and real-world problem-solving." — S. Abineshwari

Smart Suitcase

Air Humidifier

Smart Air Humidifier – Enhancing Indoor Air Quality

Developed by third-year Product Design student Dinesh Kumar, this compact ultrasonic humidifier improves air quality with cool mist and sensor-based humidity control. Its USB-powered, whisper-quiet, and energy-efficient design makes it perfect for homes, offices, and labs.

Spec :

Frame Shape : Compact portable design

Operation Mode: Ultrasonic cool mist humidification

Power Input: USB-powered (5 V DC, energy-efficient)

Noise Level : Whisper-quiet operation (< 30 dB)

Dimensions: 120 mm × 120 mm × 200 mm

“Working on this humidifier helped me understand the integration of electronics, sensor technology, and product ergonomics. It was a hands-on journey in designing something practical and meaningful.” — Dinesh Kumar M

Many Ideas, Endless Possibilities

At SIMATS Engineering, we nurture and protect our students' innovative ideas by securing patents, turning creativity into reality.

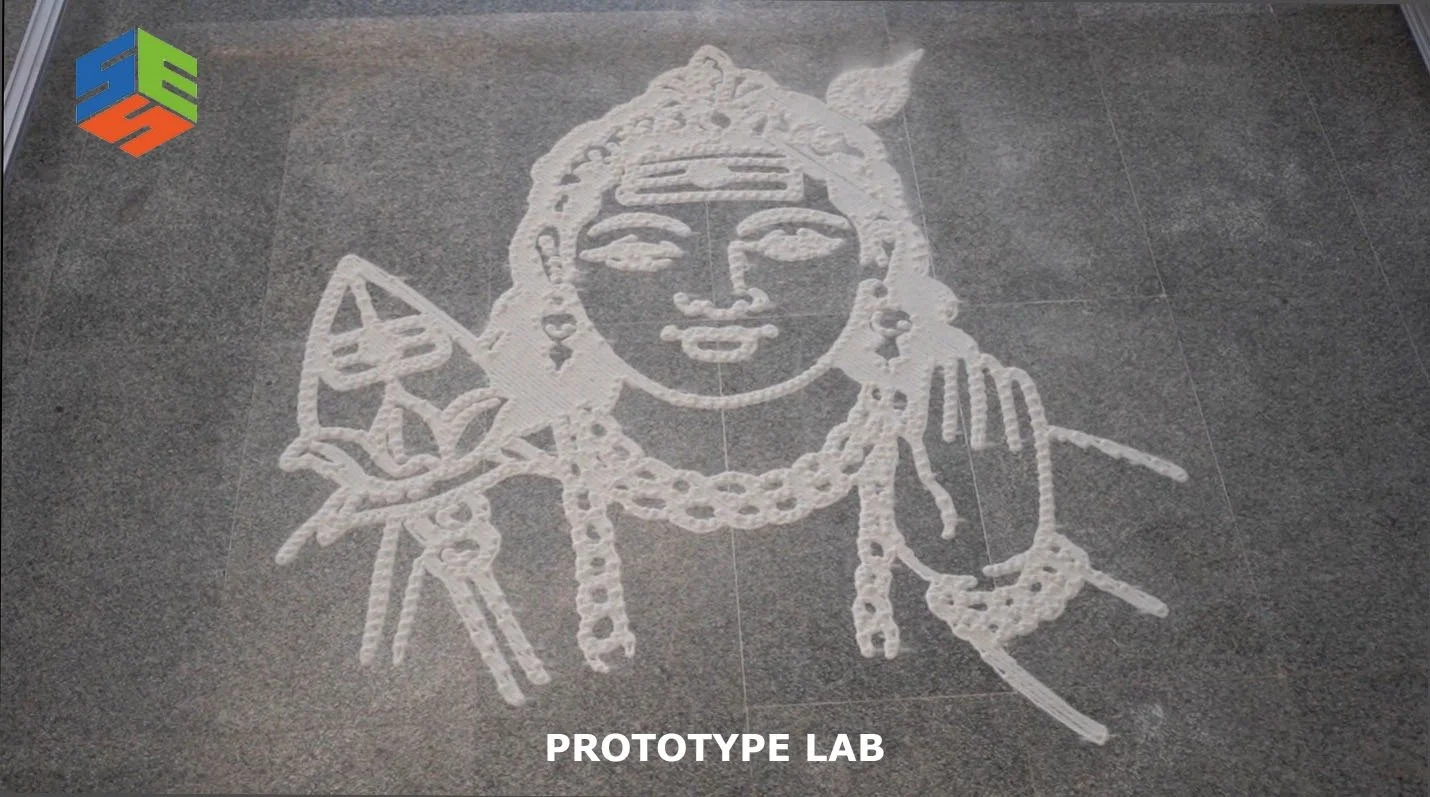

Rangoli Drawing Machine

Automatic Rangoli Drawing Machine

By Manukonda Vamsikrishna, Third-Year Product Design Student

Swarm Drone

Nut Sorting Machine

Emotipot

Automatic Card Distribution Machine

Scan QR Code

Scan QR Code

Scan QR Code

Scan QR Code

Exciting Events Ahead at SIMATS

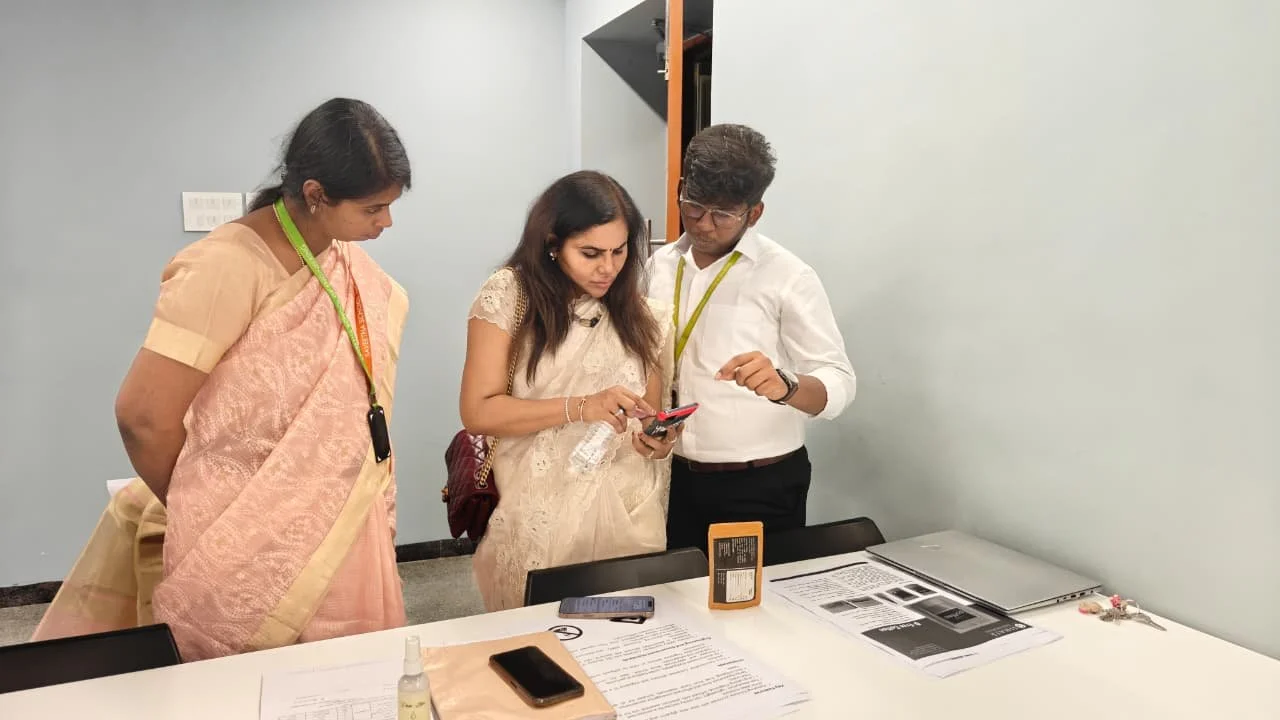

Students Pitching their innovative products to investors at startup summit 2025